富阳市乐成气体设备有限公司

主营:变压吸附制氮机,小型PSA制氮机,制氮装置,变压吸附制氧机,防爆式制氮机,移动式制氮机,PSA制氧机,过滤器

主营:变压吸附制氮机,小型PSA制氮机,制氮装置,变压吸附制氧机,防爆式制氮机,移动式制氮机,PSA制氧机,过滤器

所在地:

浙江 杭州

产品价格:

电议元/台(大量采购价格面议)

最小起订:

1

发布时间:

2024-11-13

有效期至:

2024-12-13

产品详细

变压吸附氮气设备

变压吸附氮气设备简介:氮气,占空气体积的78%,以单质的形式存在于空气之中,取之不尽,用之不尽,是无色、无害、无味的惰性气体。目前已被广泛应用于食品保鲜、粮食仓储、金属热处理、石油化学工业、宇航技术、玻璃工业等诸多领域。

变压吸附氮气设备是近来发展起来的效率高节能的新型气体分离技术。它利用空气作原料,在有电能的条件下制取氮气。 国外PSA工业制氮应用是在20世纪80年代初期,经过近30多年研究开发,变压吸附装置在降低能耗、降低投入资金、工艺流程简化、提高可靠性方面,都有了很大的进步,得以广泛应用。

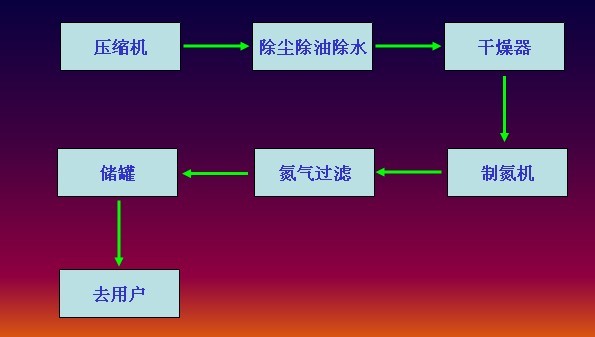

变压吸附氮气设备的基本流程与配置:根据氮气用量和使用要求,各装置的流程略有差异,但是基本流程和配置为:空气压缩机→储罐→管道过滤器→冷冻干燥机(或其他更新干燥塔)→(超)精过滤器→效率高除油器→缓冲储罐→吸附塔A/B(两塔流程)→粉尘过滤器→氮气缓冲储罐→氮分析仪→用户。空气经压缩机压缩至0.8MPa,经空气储罐冷却至常温,再经管道过滤器油液分离进入冷冻式干燥机,流经精过滤器、超精过滤器和效率高除油器除去油及液态水到达缓冲储罐,再进入碳分子筛吸附塔组成的变压吸附分离系统,压缩空气从容器底部进入后,空气中氧气、二氧化碳和水分被吸附剂选择吸附,其余组份(主要为氮气)则从出口端流出,经粉尘过滤器进入氮气缓冲罐,经氮气缓冲罐后作为产品氮气输出。之后,吸附塔经均压、减压至常压等过程,脱除所吸附的杂质组份,完成碳分子筛的更新。两吸附塔循环交替操作,连续送入空气,连续产出氮气。 氮气经计量及氮气分析仪分析纯度达标后进入氮气输送总管供使用。上述过程,由PLC控制系统自动控制。氮气纯度可高达99.99%,氮气压力基本设计在0.6MPa左右。

在一些新兴的材料行业、电子工业、集成电路、啤酒饮料等惰性气体的应用也在不断地拓展新的应用领域。

变压吸附氮气设备的应用:

化工、石油化工、精细化工生产中,氮气作为惰性保护气氛可用于反应、置换、吹扫、压力输送等工艺场合。

Psa nitrogen gas equipment

Psa nitrogen gas equipment introduction: nitrogen, accounting for 78% of the air volume, with simple substance in the form of air in, as if out of the endless, is a colorless, non-toxic, tasteless inert gas. At present have been widely applied in food preservation, food storage, metal heat treatment, petroleum chemical industry, aerospace technology, glass industry, etc.

Psa nitrogen gas equipment is the recent development of high efficiency and energy saving of new gas separation technology. It USES air as raw material, under the condition of electric energy in making nitrogen. PSA nitrogen making foreign industrial applications are in the early 1980 s, after nearly 30 years of research and development, variable pressure adsorption device in the lower energy consumption, lower investment, process simplified, improving the reliability, all had the very big progress, can be widely used.

Psa nitrogen gas equipment of the basic process and configuration: according to nitrogen dosage and use requirement, each unit process vary slightly, but the basic process and configuration for: air compressor, tank and pipeline filter, freeze drying machine (or other renewable drying tower) - (ultra) fine filter - efficient degreaser and buffer tank - adsorption tower A/B (two tower process) - dust filters - > nitrogen buffer tank - nitrogen analyzer to the user. The air compressor compression to 0.8 MPa, the air tank cooling to room temperature, then through pipeline filter oil separation into freezing drying machine, through the fine filter, ultra precision filter and efficient degreaser remove oil and liquid water reach buffer tank and then to carbon molecular sieve adsorption tower composed of variable pressure adsorption separation system, compressed air from the bottom of the container into, the air oxygen, carbon dioxide and water was adsorbent selective adsorption, the rest of the components (mainly for nitrogen) from the outlet, the dust filter into nitrogen buffer tank, the nitrogen buffer tank as a product after nitrogen output. After that, the adsorption tower are pressure, reduced pressure to atmospheric process, removing the impurity components by adsorption, complete carbon molecular sieve regeneration. Two adsorption tower circulation alternating operation, continuous into the air, continuous output nitrogen. By measuring the nitrogen and nitrogen analyzer analysis purity after standard into nitrogen transport manager for use. The above process, controlled by PLC automatic control system. Nitrogen gas purity can be as high as 99.99%, nitrogen pressure basic design in 0.6 MPa or so.

Psa nitrogen gas equipment applications:

Chemical industry, petroleum chemical industry, fine chemical production, nitrogen as inert protective atmosphere can be used in the reaction, replacement, blowing, pressure conveying technology occasion.

In some new material industry, electronic industry, integrated circuit, beer beverage, etc inert gas application is in constant develop a new application field.

变压吸附制氮设备的销售电话:0571-23218340,15268538866

公司网址:

¥电议 元